Aluminum vs Copper Conductors: Choosing the Right Size for Maximum Power Efficiency

When it comes to designing electrical systems, one of the most important decisions contractors and engineers face is selecting the right conductor material and size. Copper and aluminum are the two most common options for power transmission and distribution, but each has unique properties that impact ampacity, voltage drop, cost, and installation considerations. Understanding how conductor size relates to power-carrying capacity is critical for efficient and safe electrical systems.

Understanding Ampacity and Conductor Sizing

Ampacity is the maximum current a conductor can carry safely without exceeding its temperature rating. Copper has higher conductivity than aluminum, roughly 61% more efficient, meaning a smaller copper conductor can carry the same current as a larger aluminum conductor.

For example:

| Current Rating (Amps) | Copper Conductor | Aluminum Conductor |

|---|---|---|

| 150 A | 1/0 AWG | 2/0 AWG |

| 200 A | 2/0 AWG | 4/0 AWG |

| 400 A | 4/0 AWG | 250 kcmil |

These examples highlight why understanding conductor sizing is critical: choosing the wrong size can lead to overheating, voltage drop, or inefficiency, especially in long-distance feeders.

Voltage Drop Considerations

Voltage drop occurs when electricity travels through a conductor, losing energy due to resistance. Larger aluminum conductors are often required to maintain proper voltage levels over longer distances.

For instance, in a 500-foot run supplying a 200 A load, a 2/0 AWG copper conductor may achieve less than 3% voltage drop, while aluminum may need to be sized to 4/0 AWG to meet the same standard. Excessive voltage drop can reduce equipment efficiency, cause malfunction, or violate NEC voltage drop recommendations.

Cost vs Performance Trade-Offs

Choosing between aluminum and copper isn’t just about electrical performance — cost and handling matter too.

-

Aluminum:

-

Pros: Lighter, less expensive per pound, easier to handle for long runs.

-

Cons: Requires larger conductor size, potentially increasing labor, conduit size, and termination hardware costs.

-

-

Copper:

-

Pros: Higher conductivity, smaller size for the same ampacity, better mechanical strength.

-

Cons: Higher price per pound and heavier to install, especially for very long runs.

-

For large utility or renewable energy projects, these trade-offs can significantly impact total project cost. For example, a solar farm with 20 miles of feeders may save money using aluminum conductors despite requiring larger sizes and heavier terminations.

Applications in Modern Energy Infrastructure

Aluminum and copper conductors are used across industries:

-

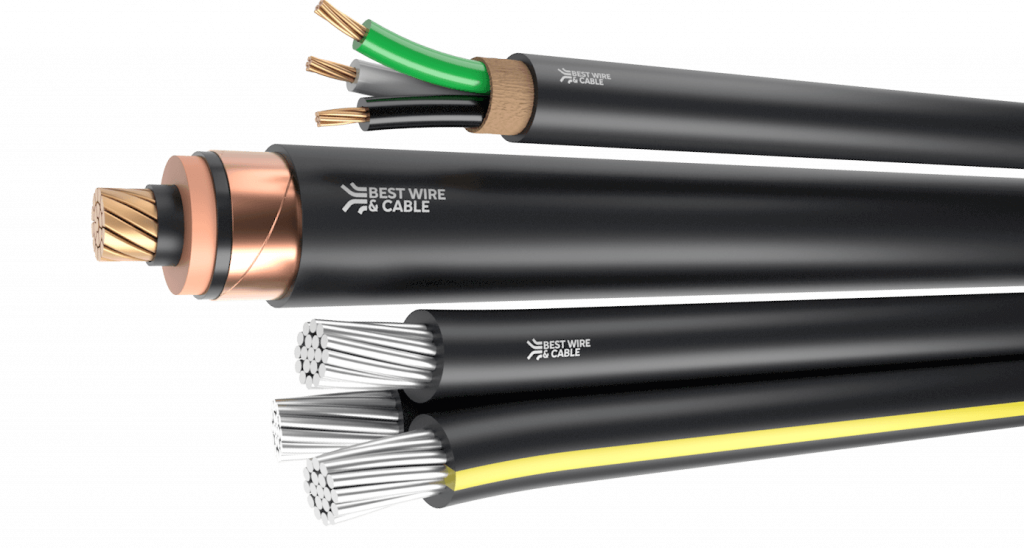

Utility Feeders: Medium-voltage feeders often use aluminum for long-distance distribution due to cost and weight savings.

-

Renewable Projects: Large solar and wind farms frequently use aluminum for collection circuits, while copper may be chosen for inverter connections where higher efficiency is critical.

-

Data Centers: High-density loads often favor copper for compact runs, reliability, and reduced voltage drop.

-

EV Infrastructure: Fast-charging networks rely on accurate conductor sizing to maintain efficiency and safety.

Choosing the right conductor material and size ensures that these systems operate reliably while meeting budget and installation constraints.

Code and Safety Considerations

Contractors must always follow NEC (National Electrical Code) and IEEE standards when sizing conductors. Key considerations include:

-

Ambient temperature derating

-

Grouped conductor adjustments

-

Conduit fill limitations

-

Voltage drop limits (often 3% for feeders, 5% for branch circuits)

Following these guidelines ensures safety, regulatory compliance, and long-term performance.

Practical Tips for Contractors

-

Use Copper for High-Density Loads – Where space is limited or efficiency is critical.

-

Consider Aluminum for Long Feeder Runs – Cost-effective and lightweight for utility or renewable projects.

-

Plan for Voltage Drop – Oversize conductors when distance or load justifies it.

-

Check Market Prices – Copper prices are historically higher and more volatile; aluminum can offer savings in certain scenarios.

-

Always Cross-Check NEC Tables – Verify conductor sizing with updated ampacity tables and derating factors.

Conclusion

Choosing the right conductor material and size is more than a technical detail — it’s a critical factor in power efficiency, safety, and cost management. Copper’s superior conductivity allows smaller conductors in space-constrained applications, while aluminum’s cost-effectiveness and lightweight properties make it ideal for long-distance feeders and large-scale renewable energy projects.

By understanding how conductor size impacts power capacity and planning for voltage drop, cost, and installation constraints, contractors, engineers, and project managers can design more reliable, efficient, and cost-effective electrical systems that meet the demands of modern infrastructure.

Resources & References

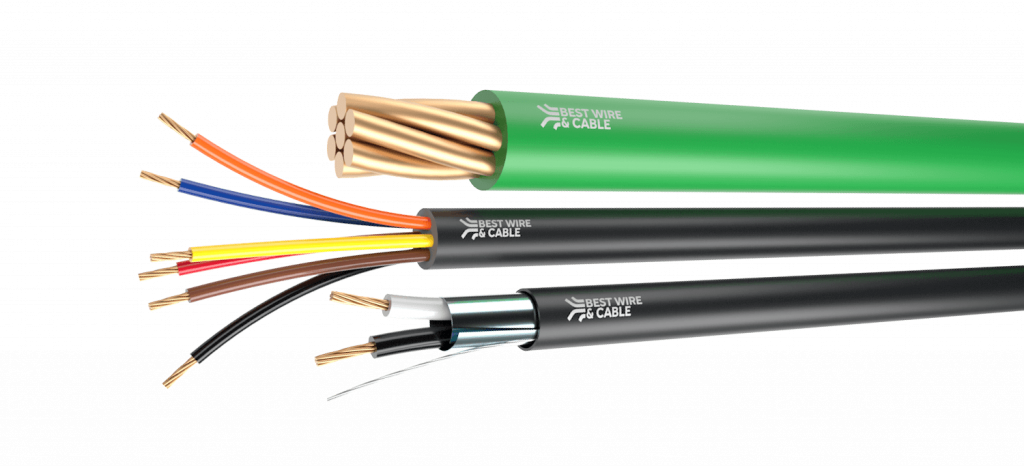

Click to view our Products